SPINE – REAL TIME REMOTE MONITORING SYSTEM FOR SITE ELECTRICAL NETWORK

Prevent and optimize

Prevent issues with the temporary electrical network on the construction site and optimize site costs using the real time remote monitoring system Spine.

WATCH THE VIDEO ->

What is the Spine system?

The Spine remote management system provides real-time monitoring for construction site electrical networks. Predictive alerts, cost management, and eco-friendly solutions help improve site efficiency, reduce costs, and extend the lifespan of equipment.

Do you want to avoid unnecessary power outages on your construction site?

The Spine system provides a predictive alert service that helps prevent unnecessary power outages on the site. If disturbances are detected in the electrical network that could cause a fuse to blow or, in the worst case, a fire, Spine will alert you immediately. The service monitors factors such as tilt load, over- and under-voltage, overload, and temperature rise.

Set and adjust alerts according to your site’s needs

With the Spine system, you can easily set and adjust alerts to meet your site’s specific needs, ensuring that any potential electrical disturbances are noticed in time and can be addressed before they cause damage.

Do you want to know the real-time load of the electrical network and its distribution?

With the Spine system, you can view the real-time usage rates of the panels and the load of the electrical network. Changes can be made to the network and load can be increased without the need for separate manual measurements, improving efficiency and saving time.

Make greener choices and avoid the use of fossil fuels

Spine also helps make environmentally friendly choices and supports reducing the use of fossil fuels, particularly in heating applications, promoting sustainability on construction sites.

Do you want to avoid excessively high temperatures and unnecessary energy consumption?

The Spine system’s environmental monitoring provides real-time data on temperature and humidity levels. A few degrees drop in temperature can lead to significant savings on your electricity bill, and excessive humidity can be quickly detected and addressed.

Optimize energy consumption and improve conditions with the Spine system

Spine helps optimize energy usage and ensure the conditions on your construction site, reducing unnecessary energy consumption and improving cost-efficiency.

Do you want to measure energy consumption in real time?

The Spine system measures real-time electricity consumption (not a MID-approved meter) and records all measurable data throughout the history of the construction site. This allows you to reliably identify the causes of potential issues and improve the energy efficiency of the site.

Track energy consumption and optimize costs with the Spine system

Spine provides complete transparency in electricity consumption, helping to optimize energy use and reduce unnecessary costs on the construction site.

Applications of the Spine System

The Spine system can be used in various projects that require precise and reliable electrical network monitoring.

The system is particularly well-suited for:

- Construction sites

- Infrastructure projects

- Industrial facilities

- Docks and shipyards

- Events

How does Spine work?

The Spine device can be built into the electric cabinet, as a modular component in a modular electric cabinet, or as a simple Plug&Play device that can be installed with any electric switch board.

The Spine device includes a central unit, power transformers, and an antenna. Inside the Spine central unit, there is a built-in eSIM that sends the collected data to a cloud service. The data can be accessed through the Spine service via a web browser. The central unit also measures the surrounding temperature and humidity.

The power transformers measure all the current passing through the panel and, thus, the Spine device, identifying imbalances between phases, overloads, under-voltage, and other electrical characteristics.

If any parameter exceeds its set threshold, Spine sends an alert to the users. The default threshold values are pre-set but can be easily adjusted.

Additional sensors, such as Ruuvi tag sensors for measuring temperature, humidity, and pressure, can be connected to the Spine system. The product development also includes a control unit for a water-based heating system.

What can be seen in the Spine service?

The homepage of the Spine service provides a concise summary of essential information about the construction site’s electrical network and its load, real-time energy pricing, real-time CO2 emissions, device location data, temperature and humidity.

Riser Diagram

The service automatically draws a real-time power distribution diagram for the construction site’s electrical network as new Spine panels are connected to the network. When the Spine device is connected to the service, the system asks for all necessary information during the QR code scan to determine whether it’s a sub-panel or a main panel and where it should be placed in the diagram.

Layer images can be attached to the power distribution diagram, marking the locations of the panels. Station layout images can also be attached, making it easier for the service user. The power distribution diagram provides an overview of the entire network, with the load of each panel indicated by “traffic lights” – green, yellow, or red based on the panel’s usage rate.

Device Page

Each Spine has its own device page in the service, providing details such as:

- Device name and ID number

- Project where the device is in use

- Device owner

- Real-time consumption and usage rate relative to available capacity

- Real-time phase-specific voltage and current

- Maximum, minimum, and average current and voltage

- Internal real-time temperature and humidity of the panel

- Historical data

Watch the video on the easy setup of Spine!

Spine is set up by scanning the QR code on the product. The service will ask for all the necessary information to position the panel correctly within the site’s power distribution diagram. The system will ask for details such as the size and number of the input cables, the size of the supplying panel, and whether it is a sub-panel or a main panel.

Technical Support

For questions related to the commissioning or use of the Spine device and system, please contact Spine Support by phone at +358 40 614 7551 or by email at support@spine-electric.io.

Products in the Spine system

-

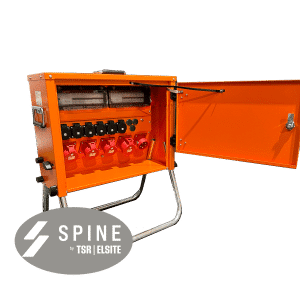

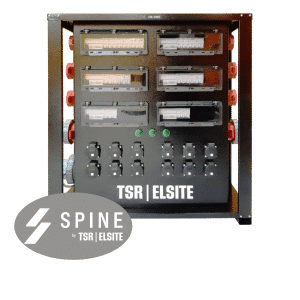

Modular main center 400A with Spine

Modular 400A Main Distribution Center for Construction Sites The modular…

-

Modular main distribution board 630A with Spine

Modular Main Distribution Board 630A – Temporary Power Solution for…

-

Modular site distribution board SCS-350

Modular Site Distribution Board SCS-350 Fastline with Spine Compatibility The…

-

Spine – automatic load management for generators

Spine Plug & Play is an intelligent, easy-to-use load management…

-

Spine for 16A-1250A centers with fixed input

Spine for 16A-1250A centers with fixed power supply is an…

-

Spine Plug & Play 125A

Spine Plug & Play 125A for remote management of power…

-

Spine Plug & Play 16A

Spine Plug & Play 16A for remote management of power…

-

Spine Plug & Play 32A

Spine Plug & Play 33A for remote management of power…

-

Spine Plug & Play 63A

Spine Plug & Play 63A for remote management of power…

-

Sub center 32A TSR-UC32 with Spine

The sub central’s supply and all outputs are protected behind…

-

Sub center 63A TSR-UC63 with Spine

The sub central’s supply and all outputs are protected behind…

-

Sub central FUC125X Spine for site cabins

The FUC125X Spine worksite electrical substation is specifically designed for…

-

Sub central with fixed incoming FUC125 Spine

Sub central with fixed incoming cable for temporary electrification at…

-

Sub distribution board 125A with Spine monitoring HUB 125/VM

Sub Distribution Board with Phase Meters and Spine Remote Monitoring…

-

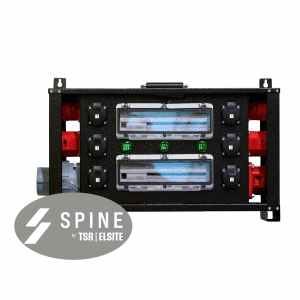

Sub distribution board with Spine TSR HUB 32A

32A Sub Distribution Board with Spine Remote Monitoring and Phase…

-

Sub distribution board with Spine TSR HUB 63A

Sub Distribution Board with Phase Meters and Spine Remote Monitoring…