spine – REAL TIME SITE ELECTRICAL NETWORK MANAGEMENT AND MONITORING SYSTEM

Spine prevents site problems and brings information to support decisions

- Preventing problems at site with proactive alerts

- Versatile cost management tool

- Helping to make carbon-neutral choices

- Collecting information and learning from it

- Available to all 16A – 1250A switch boards

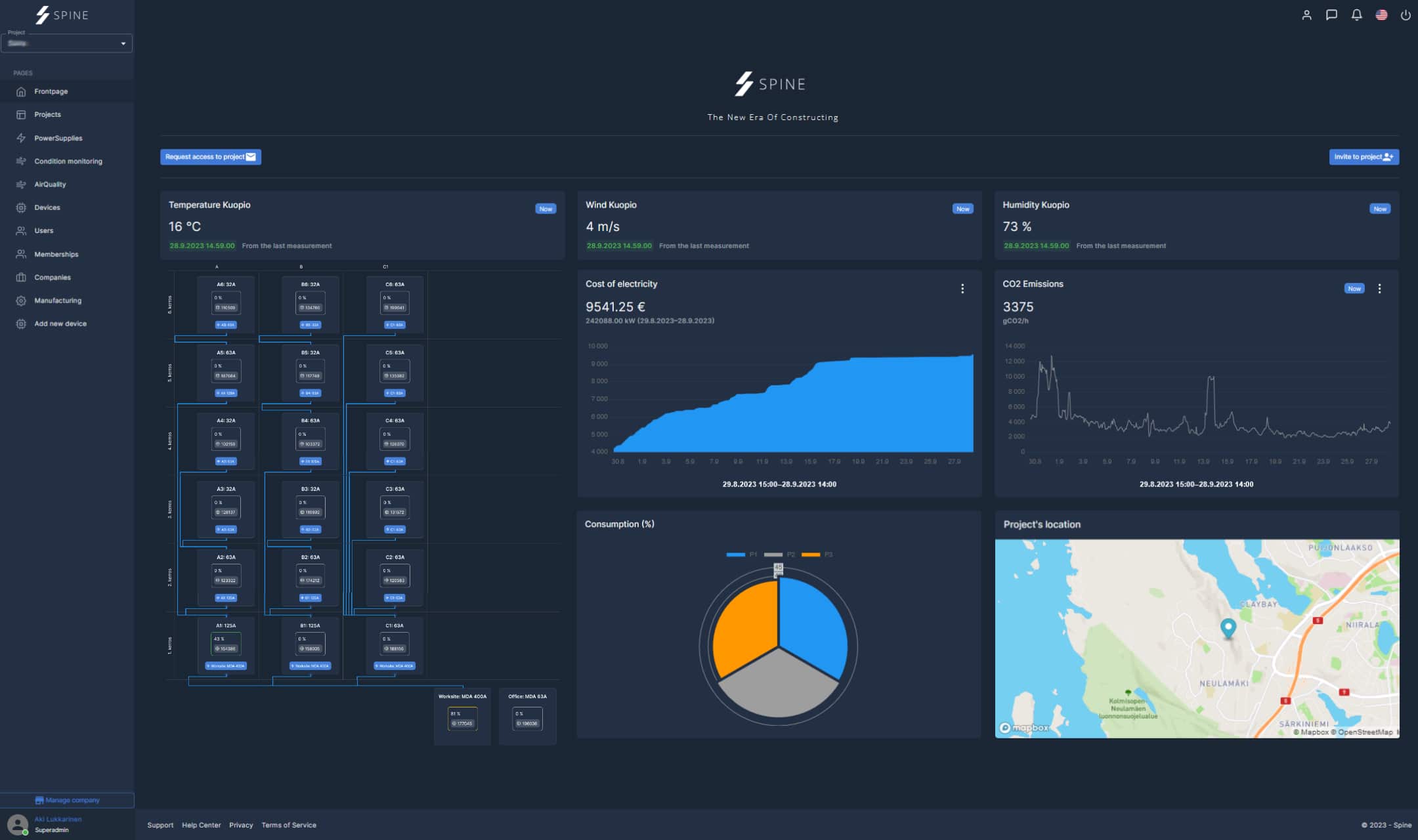

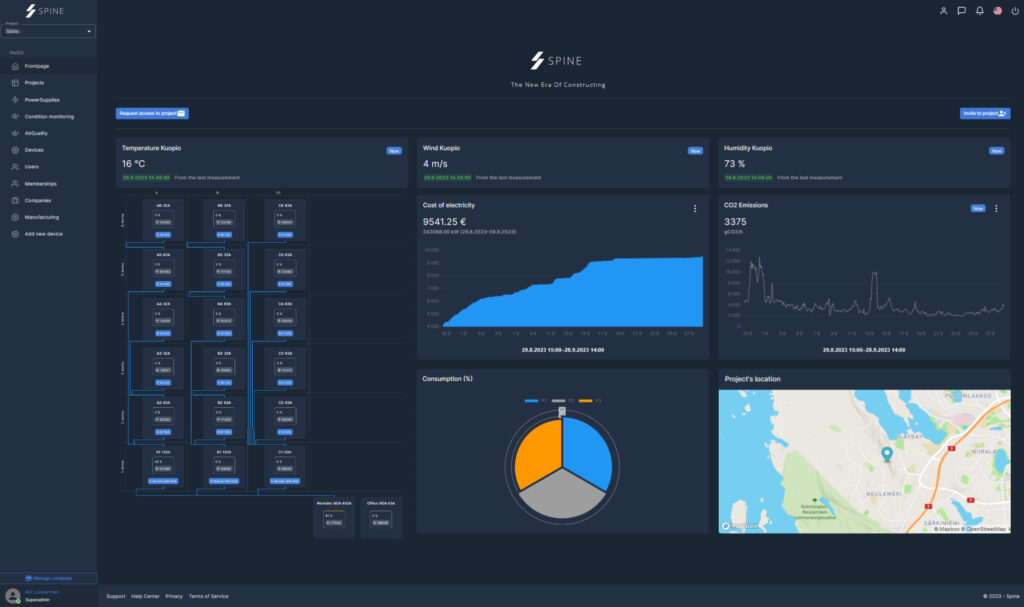

Project front page

The Project’s front page contains real-time and historical information about the project:

- Electricity consumption and price

- Phase load distribution

- CO2 emissions

- Device location information

- Riser diagram

- Historical information from the life cycle of the project

- Temperature, humidity and wind based on location

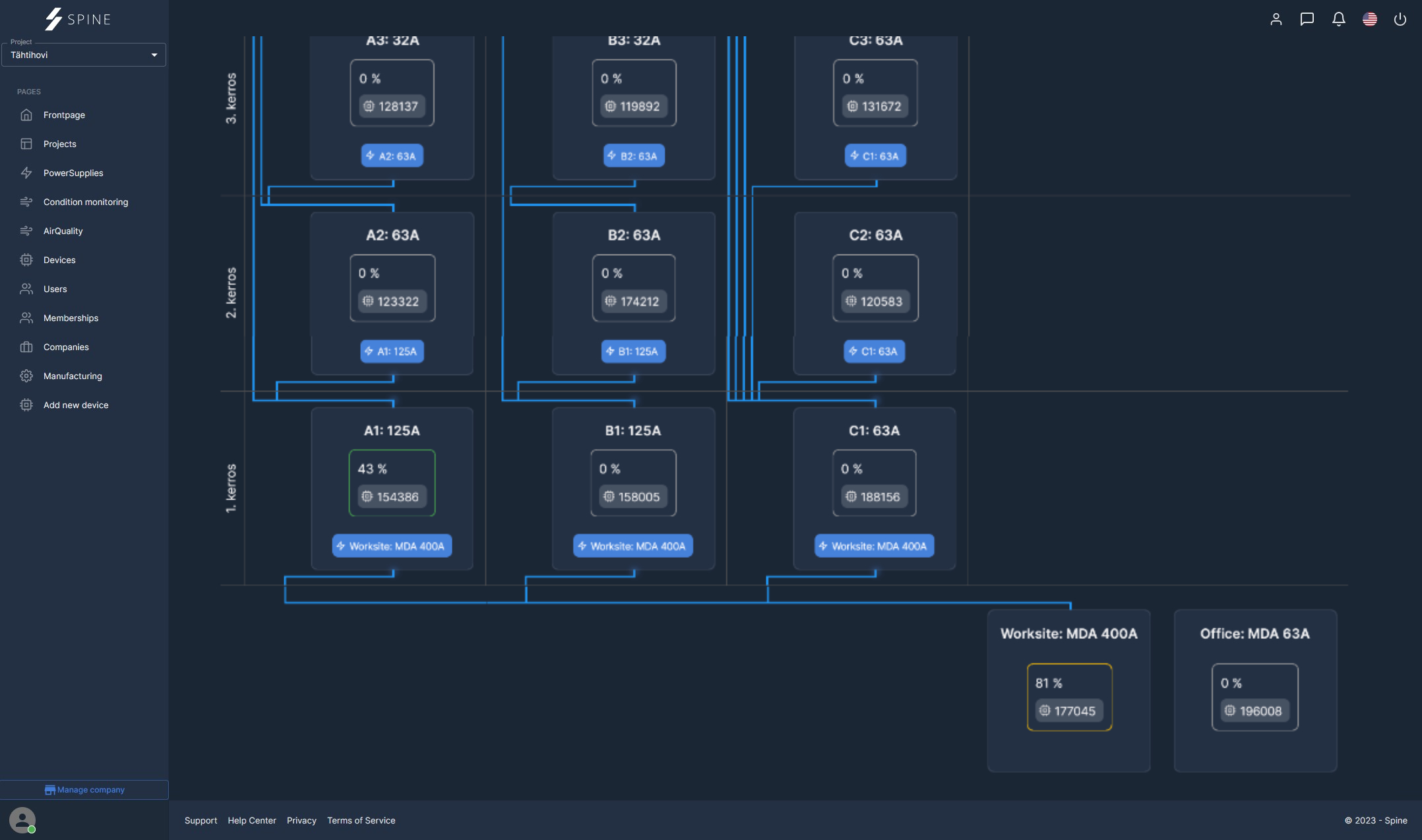

Riser diagram

The Riser diagram is an overview of the entire electrical network of the construction site. Spine’s real-time riser diagram shows all the centres of the project at a glance.

Each center is named and connected to the system at the site using a QR code. Spine automatically places the center in the correct position on the diagram. The diagram can be customised according to the project.

The centre-specific load is indicated in the diagram as a percentage, and potential problems are highlighted with a red attention colour. The diagram’s animation shows the current flow.

The riser diagram can be included as part of the site safety plan and orientation material.

From the diagram, you can go directly to the Device page of each center, which has more detailed information about the individual center.

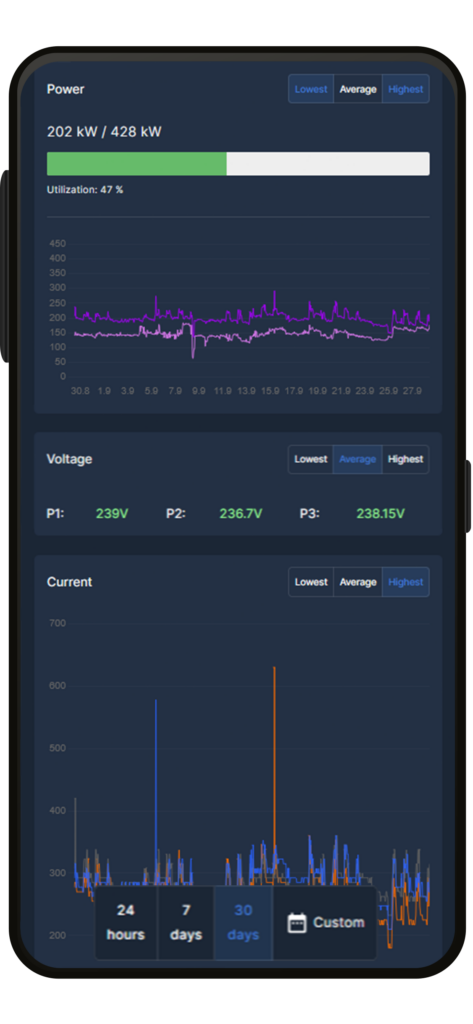

Device page

In the Spine system, each center has its own Device page where you can find:

- Device name and ID number

- The project where the device is used

- Device owner

- Real-time consumption and utilization rate

- Real-time phase-specific voltage and current

- Real-time temperature and humidity percentage inside the center

- History information

Spine Benefits to fleet management

- The life cycle of the fleet is extended thanks to proper use.

- Locating faults becomes easier.

- Equipment abuses are easy to identify and point out even afterwards.

- Device usage information for the entire life cycle.

- Device location information based on cell tower data.

- The device can be named with the ID number of the rental company.

- Recognizing the need for maintenance gets easier.

How does Spine prevent site problems in advance?

With the help of Spine, the factors that may cause problems can be eliminated even before problems develop. When the system’s alarms are activated, the construction site receives information in good time, e.g. about undervoltage, skewed load, overload, fault situations and whether the device is on at all.

With the help of Spine, the construction site’s electrical network can be built in a planned way, and information about the formation of loads remains under control.

Costs can be anticipated and possible maintenance visits carried out during normal working hours and not as expensive emergency visits in the evenings or on weekends.

How much do problems at site cost?

The electrical network plays a critically important role on the construction site, and that’s why it’s good to think about how much it will cost, for example:

- Frozen concrete casting

- Power failure

- Additional maintenance visits

- Fires or melting of the device due to continuous overload

- Darkening of the lighting on the construction site or switching off of the heating

- Shutdown of critical pumps or other equipment

Cost management with Spine

- Predictability of costs

– A real-time snapshot of the site’s electrical network

– Alerts that are known well in advance help predict the workload

– No unnesseary site visits - Real-time planning

– The site works more independently, because the system tells how much additional load can be connected to the centers

– The design feature of the system reduces expensive designer work hours and facilitates electrical network changes made during construction time - Reducing excess capacity

– No need for “just in case” too big hubs and cables

– Smaller centers are faster to connect and their installations can be done without ground cables - It becomes easier to identify the need for maintenance

– e.g. A rise in temperature inside the center can indicate loose connections or leaks that require maintenance to ensure safe operation.

Collecting information and learning from it

By using the Spine system and gathering information, even experienced construction site electrification professionals get useful information. Based on the information collected during the entire projects, investment decisions for the next project can be based on knowledge and verified experience.

During the project, the use of the electricity network’s capacity can be optimized and excess capacity can be reduced. Investments can also be targeted more precisely to equipment of the right size and according to the need.

Spine guides you to make carbon-neutral choices

With the help of Spine, the capacity of the electricity network is identified and any excess capacity can be put to useful use. A good example of an ecological solution made by identifying excess capacity is to heat the upper and lower castings in a green way with electricity instead of fossil oil or gas.

The life cycle of the equipment is extended thanks to proper use. With good maintenance and proper use, you can get years more use time in the life cycle of the equipment.

Spine’s real-time monitoring of electricity consumption and price helps to schedule activities on the construction site if possible. The price of electricity can be monitored both with spot prices and with a fixed kWh price.

The CO2 counter monitors the site’s carbon footprint in real time. The reading can also be taken as historical information and used e.g. in marketing, telling about the carbon-neutral construction method.

Spine product range

- Completed TSR-Spine site smart electrical centers with Spine built in. Centers are available in sizes 16A-1250A.

- Plug & play Spine is a solution offered as an add-on to existing centers, where Spine is connected to the center’s supply with a plug and a box. Plug & play is available for 16A-63A centers and ≥125A centers.